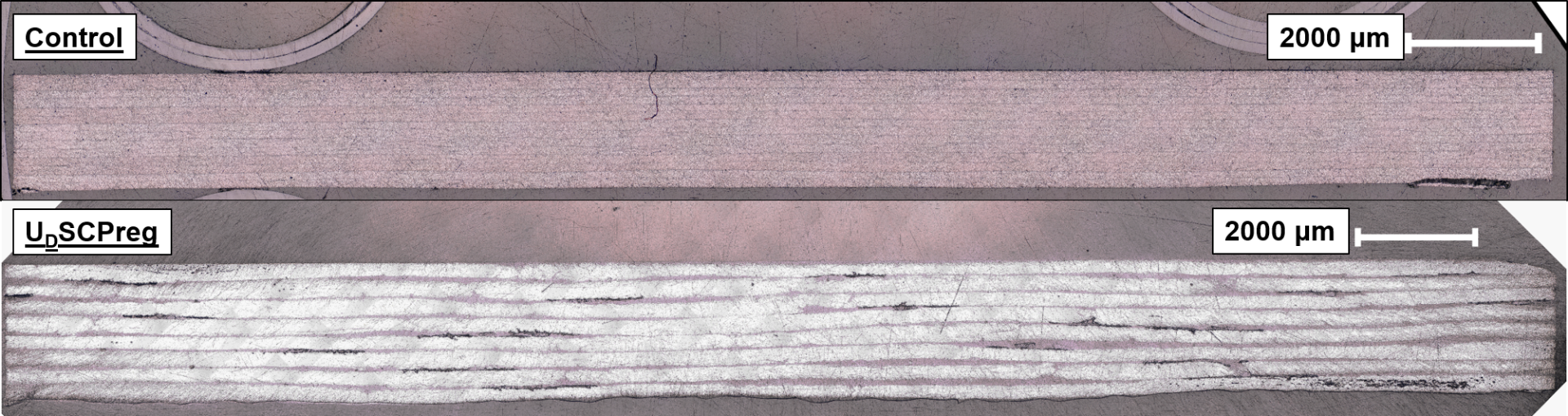

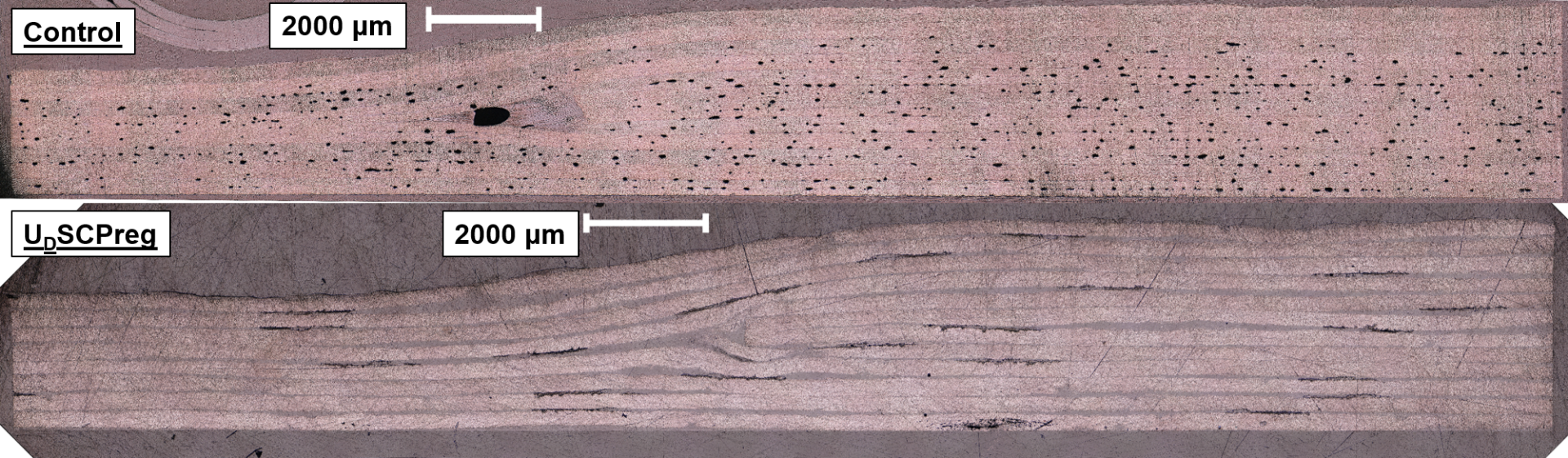

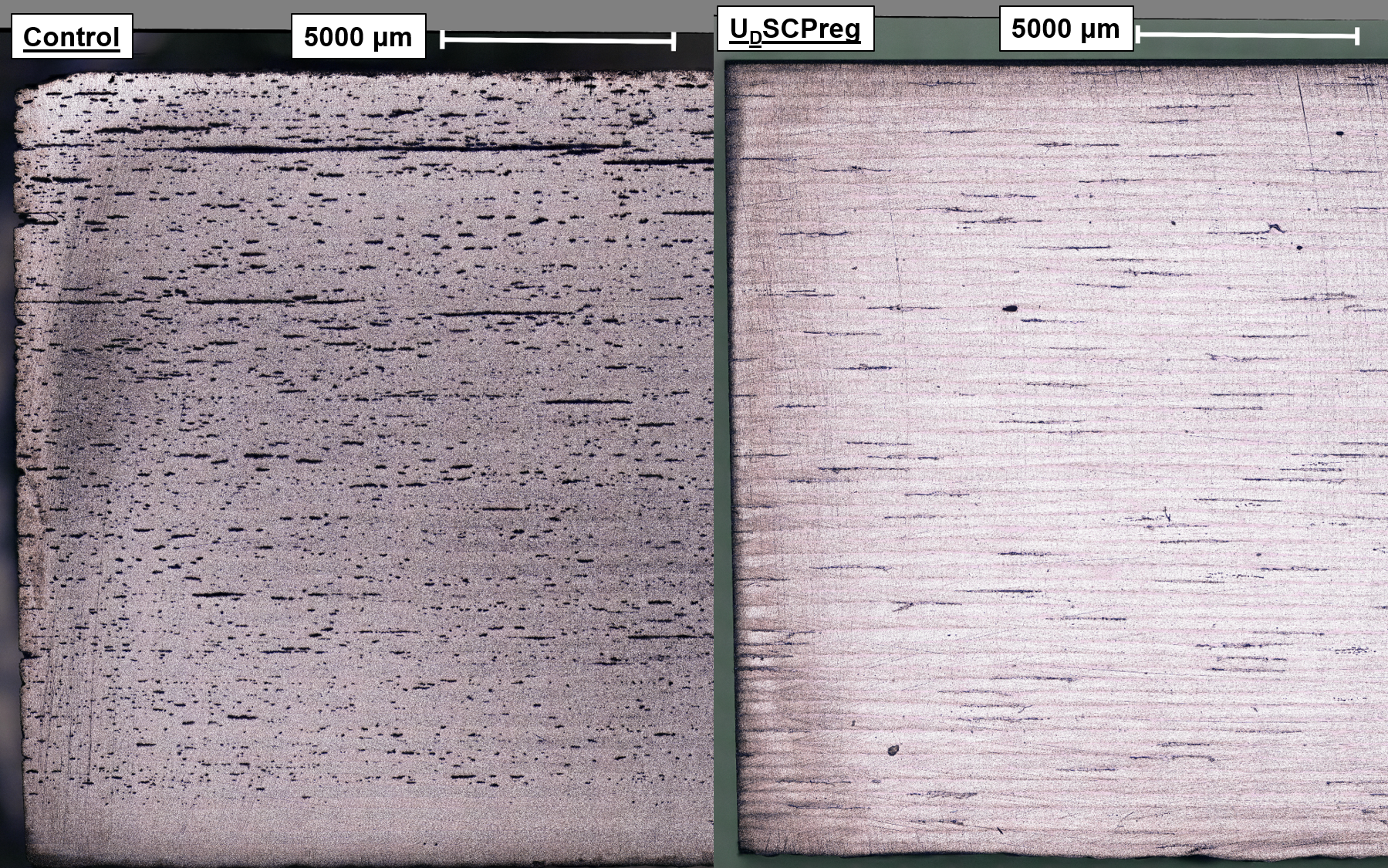

Micrographs for the flat laminate baseline. Note how the control is seemingly free of voids, while USCPreg shows visible porosity.

Researcher – Patricio Martinez

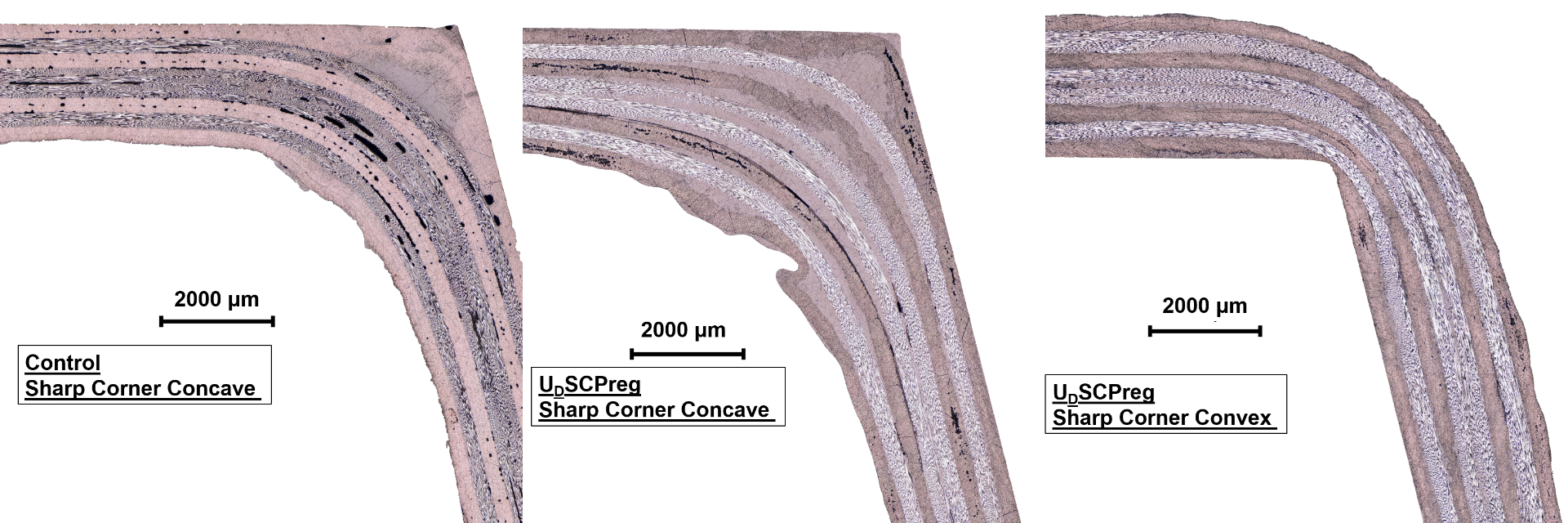

Carbon fiber composite parts commonly include complex features such as corners and curvature, internal ply drop-offs, and thick sections. These features can cut off or limit internal air evacuation pathways, or provide pressure gradients in the part, resulting in entrapped voids and resin accumulation. We seek to, by using a novel prepreg format, minimize the effects these geometric features have on internal porosity.

A prepreg format being currently studied and developed, USCPreg, has been shown to reduce the impact of non-ideal processing conditions on internal porosity. This study adds upon that, showing that similarly, USCPreg can be used to minimize the increase in internal porosity due to complex part geometry.

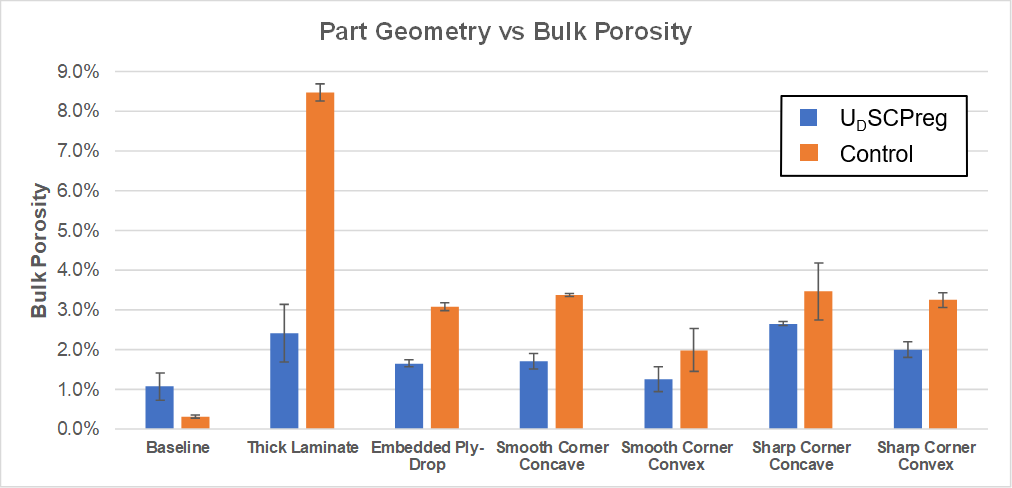

The study compared a common industry UD prepreg, the control, to USCPreg. Seven different geometries were studied: A flat laminate to use as baseline, a laminate with an internal ply-drop, a laminate with 8 times as many plies, and two different corners, sharp and smooth, each with a concave and convex geometry.

From the results, it was seen that while USCPreg may not have as low internal porosity for the flat baseline, the increase in porosity due to complex geometries is lower when compared to the control.