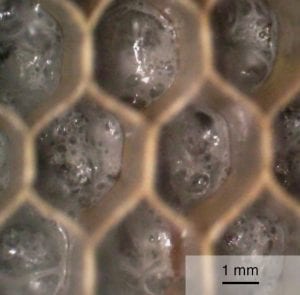

Figure 1) Sample of images obtained of the adhesive bond-line during cure using the Mini Autoclave fixture.

Researchers: Dan Zebrine, Mark Anders, Timotei Centea

Summary:

The adhesive bond-line transfers load between the facesheet and core in honeycomb sandwich structures, and defects (such as porosity and poorly-formed fillets) in the bond-line can reduce mechanical performance of the whole structure. As part of Development of a physics-based process model for co-cure bonding of honeycomb-core sandwich structures project, lab-scale studies are performed to develop an understanding of the physics of bond-line development.

Traditionally, parts are analyzed after cure to identify defects and assess bond-line quality. This method, however, answers only if defects form, and now how. Using the Mini Autoclave fixture, we can observe the adhesive bond-line in half-sandwich structures as they cure, providing insight into the dynamic mechanisms by which defects form (Figure 1).

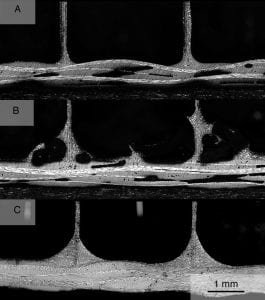

For a prepreg and adhesive pair used in aerospace sandwich structures, we identified two separate defect formation mechanisms. Low core pressure (vacuum) causes disruption of the film adhesive, resulting in sandwiches with poorly-formed fillets (Figure 2A). Residual solvent in the prepreg evolves and gets trapped in the bond-line as voids at ambient core pressure (Figure 2B). When the core is pressurized beyond ambient, defect mechanisms are suppressed, resulting in sandwiches with well-formed, void-free fillets (Figure 2C).