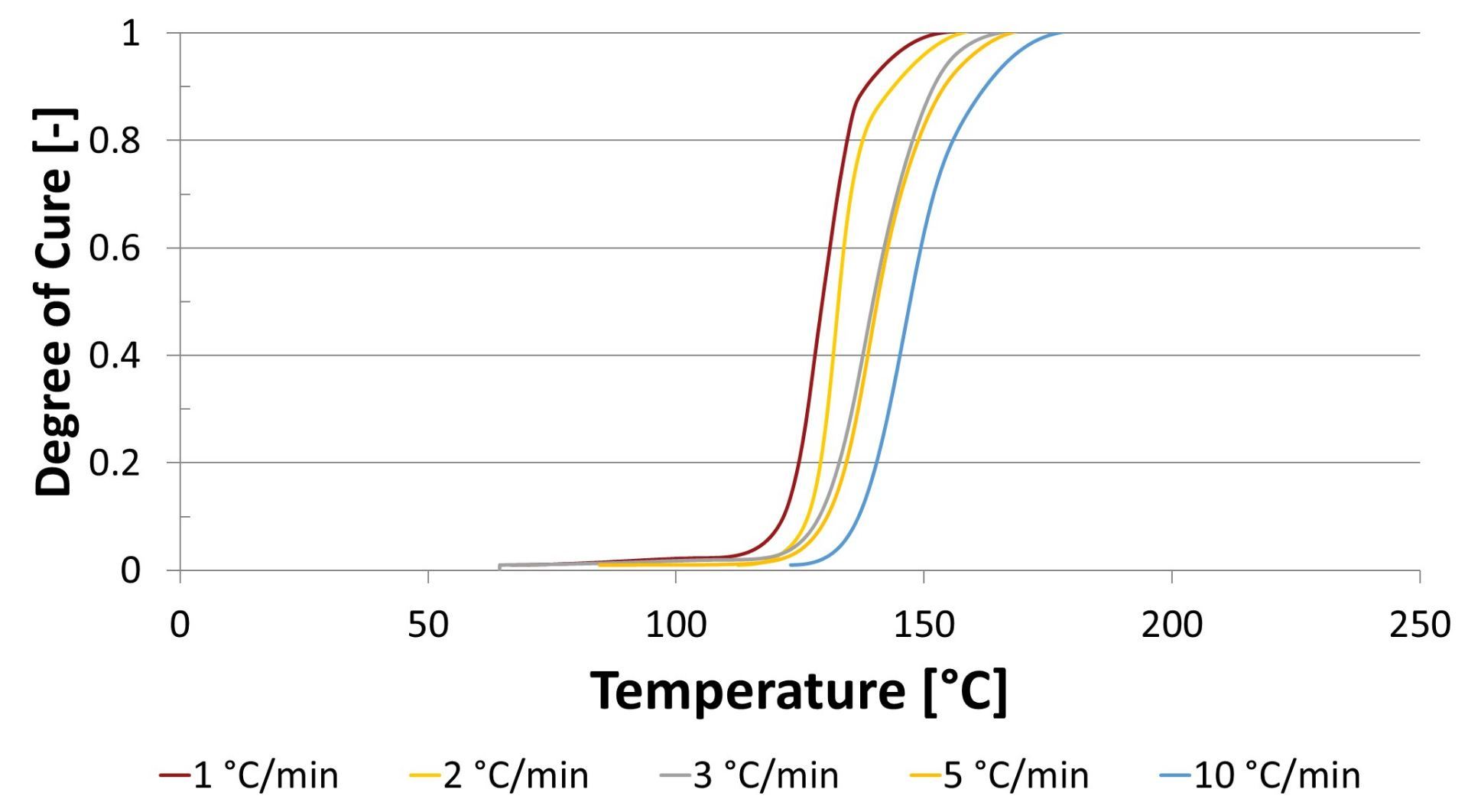

Matlab model of cure cycle to help select optimized cure conditions

Researcher – David Bender

As new industries outside of aerospace are looking into using composites, being able to manufacture high quality composites quickly is becoming more important especially for automotive industries. Many techniques from resin transfer moulding to filament winding exist for composite manufacturing however, the potential scalability and precision from utilizing prepregs lends itself to fast manufacturing processes. However many prepregs are currently designed for use in autoclaves, whose expense and slow processes prevent use in industries outside of aerospace yet can guarantee high quality parts. Although many out-of-autoclave prepregs exist, they don’t ensure high quality especially for faster cure cycles.

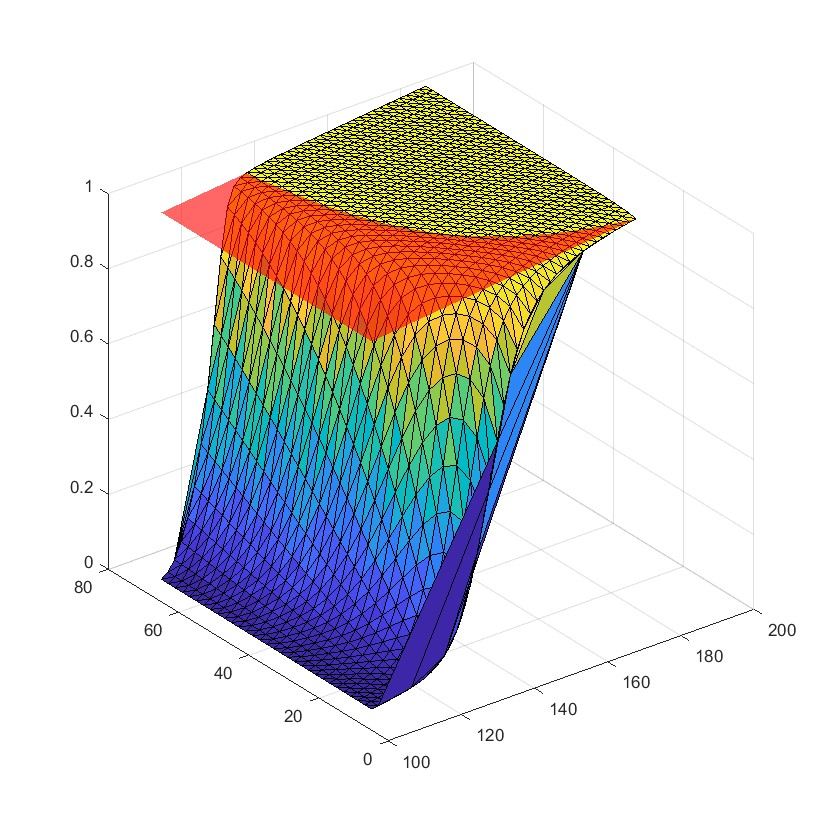

Here at USC we are investigating novel prepregs the combine USCpreg format with faster curing resins to enable a material capable of fast manufacturing. We are analyzing the factors that affect part quality from resin impregnation to air evacuation. We are simultaneously analyzing thermal kinetics and rheology to incorporate these variables into a model that will help optimize prepreg quality and shorten cure time.