FFF & DWT

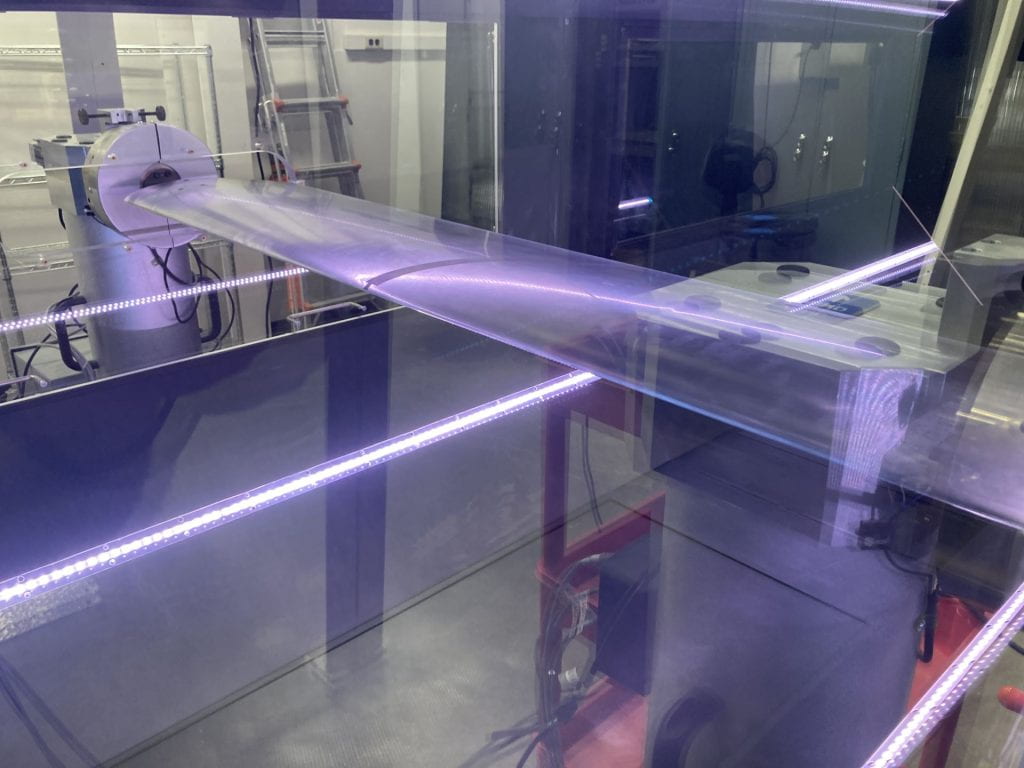

In May 2023, we had a ceremonial ribbon-cutting and inauguration of our Fabulous Fluids Facility, in which the renovation of the Dryden Wind Tunnel was a key component. FFF serves to coordinate, collect and defragment many of the various fluid mechanics experiments on campus. The 3 major components are the Blue Water Channel (BWC), stratified fluids tank and DWT.

Many moons ago, plans were hatched, and re-hatched, and re-hatched again to upgrade certain parts of DWT, so as to improve the reliability and throughput of the whole operation. The following modifications were implemented:

- replace the fan motor and controller

- replace test sections with 3 interchangeable modules; each one can host an experiment

- upgrade the force balance

- replace/re-write all control and analysis software on a common Matlab base

- reconfigure and expand the control room and model-building facility

- give it all a new coat of paint!

These changes and upgrades were driven by Alejandra Uranga, and Michael Kruger has been responsible for a great deal of work in setting up and commissioning the new setup, which was mostly complete in December 2021. The new tunnel was first turned on in March 2022, and by the beginning of 2023 we can say that it is nearing production mode, though numerous flow quality tests will be continuing through the year.

Here’s a part of the journey in pictures:

Under construction

Opening Day