|

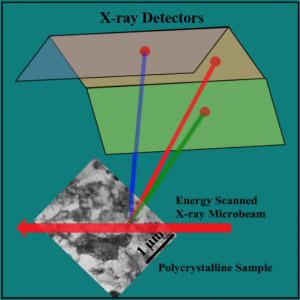

We now have developed a technique that can assess the full strain tensor such as in Equal Channel Angular Pressing (ECAP). We now have developed a technique that can assess the full strain tensor such as in Equal Channel Angular Pressing (ECAP).

Harper-Dorn Creep

Creep is referred to as the permanent deformation at stresses usually smaller than the yield strength. Creep is a diffusion controlled phenomenon, hence it becomes important only at high temperatures (>0.5 Tm where Tm is the melting temperature). Stress exponent, activation energy and dislocation density are a few of the signatures of a creep mechanism.

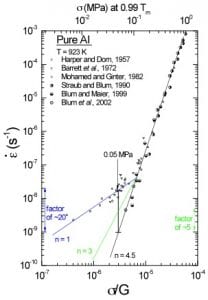

Creep occurring at very low stresses (<10-4 – 10-6G, where G is the shear modulus) and at very high temperatures (>0.9Tm) belongs to the Harper – Dorn creep regime. Conventionally, Harper-Dorn creep is identified with a stress exponent of 1, activation energy equal to volume diffusion and stress independent dislocation density. As shown in the figure, stress exponent value in the Harper – Dorn regime is controversial!

Solving the controversy: We’re making new insights into this 50 year old problem, which is important in understanding a few industrial processes and geological phenomenon (e.g. in glacier flow, geodesic plate movement, etc)

Single crystalline samples free from grain boundary effects Ultrahigh purity (99.999%)

Low purity samples do not show deviation from 5-power law creep in the Harper-Dorn regime

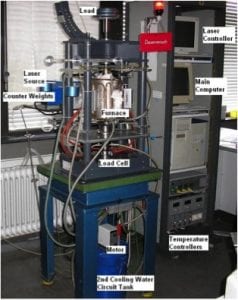

Non-contact laser based extensometer

Contact based extensometers, e.g. LVDT may exert enough friction to influence the applied very low stresses

High strains attained in tests to achieve steady state

Many of the studies reporting conventional Harper-Dorn creep failed to reach steady state

Constant load as well as load cycling tests

No difference in results between the two kinds of loading procedures

Large sized samples (diameter = 24mm) as well as small samples (diameter = 7mm)

No size dependence observed

The creep behavior in the Harper-Dorn creep regime was identified with a stress exponent closer to n ≈ 3 rather than the conventional value of n = 1. When plotted as the steady-state creep rate against the normalized stress on logarithmic axes, the present results are in good agreement with most of the earlier experimental data for high purity aluminum along with the early results of Harper and Dorn when their data is plotted without including a threshold stress. The dislocation densities measured within this low stress region are consistent with the behavior anticipated from a direct extrapolation of similar dislocation density data recorded in the conventional power-law region at high stresses. The activation energy is the same as the activation energy for the lattice diffusion. A dislocation network model can accurately capture the deformation behavior in the Harper-Dorn creep regime.

|