The information on this page was prepared by:

| Austin Davis | williamd@usc.edu | Civil/Environmental Engineering |

Biomass: Biopower

Biopower is divided into four main fields of energy generation: Direct-Fired Combustion, Co-firing, Gasification, and Small Modular production facilities.

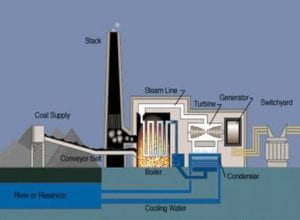

The Direct-Fired Combustion technique is very similar to the one used by the fossil-fuel fired power plants of today. Below right is a diagram of the typical fossil-fuel fired power plant. In a biomass plant, the basic difference is the use of biomass as opposed to coal. According to the Department of Energy, of the estimated 14,000 MW worldwide biomass generation capacity, Direct-Fired Combustion in the United States alone is responsible for 7,000 MW, making direct-fired combustion easily the most popular of biopower generation methods.

As for the specifics on direct-fired combustion, typical plants produce somewhere between 20MW and 50MW, compared to the 100-MW to 1500-MW range of coal-fired systems. The current efficiency of most plants usually hovers around 20%, and the Department of Energy places generation costs at 9 per kWh. Other sources contend that costs can range from 6 cents to 12 cents per kWh. In perspective, a few kilowatts are enough to power an average U.S. home for one year. At left is a wood-fired combustion plant in Michigan

Co-firing, another of the biopower technologies, is the process of replacing a portion of coal in an existing power plant boiler with biomass. This can be done by either mixing biomass with coal before the fuel is introduced into the boiler, or by using separate fuel feeds for coal and biomass. As up to 15% of coal (by heat content) can be replaced with biomass, there can be a significant reduction in harmful SO2 emissions. Another benefit to co-firing is its low cost. Only small adjustments need be made to the original plant, and once put into action, co-firing costs are so low that they include only the biomass fuel price and preparation at the plant ranging from almost nothing up to $.04 per kWh. In addition there is little to no loss in the overall efficiency of the plant.

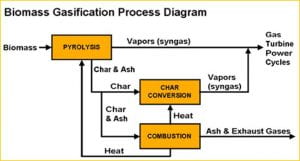

One of the more promising areas of biopower technology, gasification, is a thermochemical process that converts solid biomass to a clean fuel gas form. Because of the variety of biomass materials that can be used in gasification along with the relative ease with which gaseous fuel can be distributed, gasification is extremely flexible and may be implemented to use a wide range of energy conversion devices to produce power including gas turbines, fuel cells, and reciprocating (internal combustion) engines. The Department of Energy has predicted that advancing gasification technologies could generate power for a cost of around 5/kWh. Efficiencies from gasification can reach 60%.

A major step in the gasification process, Pyrolysis, is defined as the anaerobic thermal decomposition of biomass at high temperatures (greater than 400 F). End products of pyrolysis include a mixture of solid, incompletely combusted biomass (char), liquids (oxygenated oils), and gases (methane, carbon monoxide, and carbon dioxide) with proportions determined by operating temperature, pressure, oxygen content, and other conditions.

A major step in the gasification process, Pyrolysis, is defined as the anaerobic thermal decomposition of biomass at high temperatures (greater than 400 F). End products of pyrolysis include a mixture of solid, incompletely combusted biomass (char), liquids (oxygenated oils), and gases (methane, carbon monoxide, and carbon dioxide) with proportions determined by operating temperature, pressure, oxygen content, and other conditions.

Fixed-Bed Gasifiers, one of the more successful gasification designs, produce power through a process in which the biomass is fed from the top of the gasifier and passes through each stage as it settles to the bottom. The product gas is removed from the top and the ash from the bottom. Reasons for the success of the fixed-bed gasifier include its high combustion efficiency (actual heat produced/heat potential) and relatively simple design. However, there is a drawback in the increased handling costs of biomass as the fuel input must be large, dense, and uniformly sized.

The last of the four biopower technologies, small modular biopower production facilities have the potential to help supply electric power to the billions of people in the world who currently live without it, being especially applicable to developing countries. Most possible beneficiaries live in areas where large amounts of biomass are available for fuel and as a result small systems have the potential to provide power at the village level to serve many of these people and their industrial enterprises.

In fact, these small biopower production systems are simply small versions of the gasification and combustion plants. According to the DOE, there are currently four modular biopower operations in the United States : Community Power Corporation in Aurora , CO , Carbona Corporation, Atlanta , GA , External Power, Indianapolis , IN , and Flex Energies Inc., Mission Viejo , CA .

Each operation is involved in unique research and development issues. Units produced by Community Power Corporation, will be designed to generate power in the 5 to 25 kW range by gasifying biomass fuels such as coconut shells and husks, bagasse, rice hulls, wood residues, rubber wood, and palm nut shells.

Carbona Corporation is designing an updraft gasifier system (right) capable of producing somewhere between 1 and 5 MW per year.

External Power is producing residential-scale biomass-fueled systems designed to generate home heat and power (picture at left). First generation units will be capable of producing up to 1 kW of electricity in addition to heat for water and space heating in single-family homes.

Units produced by Flex Energies Inc. will be designed to generate 30 kW of electric power using biogas or gasified wood or crop residues. The system will be mounted onto a trailer, giving it the capability to move to the location of the fuel supply such as a landfill. The cost of power from landfill biogas (methane), one source of biopower for the system, can range from 3.5 to 7.9 cents per kilowatt-hour. In addition, because methane is 25 times stronger than carbon dioxide in terms of its global warming impact, utilizing it for energy production instead of allowing it to escape into the atmosphere is very favorable.